Self lubricating bronze plates

Our Bronze Wear Plates have been proven to run successfully in an extensive range of industrial applications.

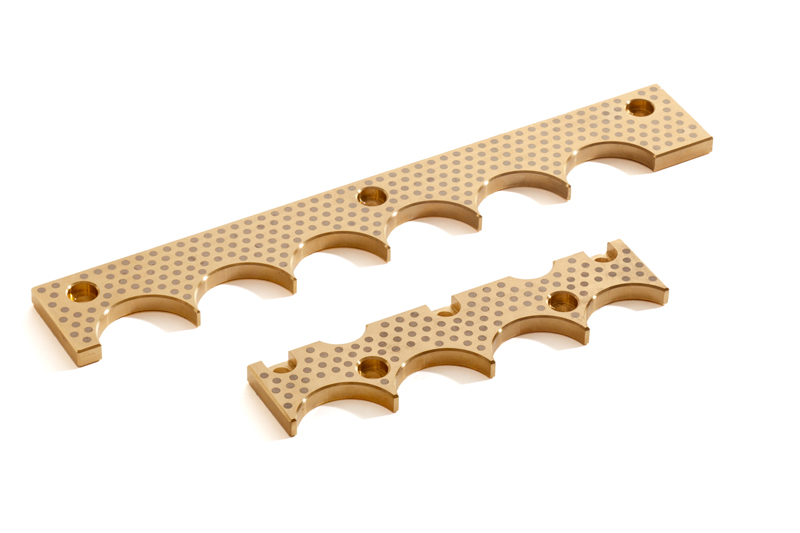

Self Lubricating Bronze Plates

Our BG series is our range of self-lubricating bronze plates. They are used in applications where the plates is required to continually operate in hard to reach or inaccessible areas where it is difficult to apply manual lubrication.

They are also used in a range of applications where it is not possible or desirable to use oil or grease as a lubricant. The plates are totally maintenance free, offer a long service life and decrease maintenance time required by plates requiring external lubrication.

Graphite Plug Plates

The bronze plate is manufactured with machined holes and/or grooves into which graphite is inserted. These graphite plugs act as the lubricant between the shaft and the plate. The graphite inserts provide a slippery coating that acts as an ongoing, reliable lubrication between the surfaces.

This type of plate is often referred to in the market as SelfLube, plugged graphite, graphited or simply self-lubricating.

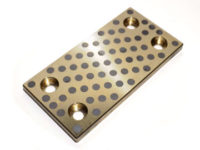

Bronze Plates with External Lubrication

Our BR Series comprises our bronze plates range which are designed and manufactured to operate with external lubrication. The superior range of bronze alloys we offer and the large variety of compatible lubricants in the market allow these plates to be used in a wide spectrum of operating conditions.

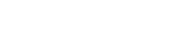

Bronze Slide Rails

Slide rails are widely used in industry across a large variety of different applications to control the motion of a load along a linear path. They are also commonly referred to by terms such as sliding guides, guideways, linear rails, guide bars, linear bearing rails and so forth. Mecauto’s bronze slide rails are manufactured to carry high loads, minimise friction between the surfaces and offer high levels of accuracy and a long service life.

Bronze alloys for wear plates

Bronze is an ideal metal for the manufacture of wear plates due to its low friction coefficient compared to other metals allowing a longer life of the assembly. The base material we use is rectangular bronze bars manufactured at Wisco – the largest and most complete bronze foundry in Europe.

As part of the Wisco group, Mecauto has immediate access to Europe’s most extensive stock of rectangular and square bars in the most demanded bronze alloys, high tensile brasses and aluminium bronzes. In addition, we offer quick turnaround for alloys and sizes not currently in stock to ensure the fastest delivery times of bronze wear plates in the market.

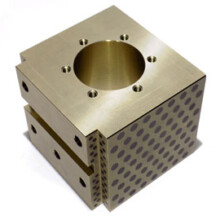

We manufacture a wide range of bronze wear plate formats and shapes, including.

Wear strips

L-gibs

V-gibs

V-block

Keeper blocks

Guide blocks

Stop blocks

Square gibs

International Service

Speak to our highly knowledgeable team regarding your requirements

Manufacturing Processes

We use state of the art machining and turning centres to manufacture bronze wear plates, with lengths greater than 2 metres, to the exacting specifications of our clients, ensuring industry leading performance, durability and wearability. Our machining process covers all aspects of the manufacture of the wear plates including lubrication grooves and other necessary configurations. We offer flexibility and are able to manufacture single plates as well as larger batches or entire series.

Other types of Self Lubricating Bronze Bearings

Are you interested in our products?

Request a no obligation, tailored quote.